Mirza Mackovic

Dr.-Ing. Mirza Mackovic

Project description

Glasses are in general believed to be isotropic materials. However, it is well known that structural anisotropy can be introduced during the processing of glasses [1]. Lund and Yue [2] highlighted the importance of structural anisotropy on the mechanical properties, by showing that structural anisotropy plays a crucial role for the significantly increased tensile strength of continuous glass fibers compared to the bulk counterpart of same composition. Even though study of glass anisotropy has recently attracted renewed interest [3], and deformation-induced structural anisotropy has been shown for a variety of glassy systems [4,5], a mechanistic understanding how mechanical loading leads to structural anisotropy in oxide glasses and how this anisotropy affects their mechanical properties is still largely lacking. As part of the DFG priority program SPP1594 “Topological Engineering of Ultra-Strong Glasses” and directly associated with the present GRK1896 program, the aim of the present project is to understand how structural anisotropy develops in silicate glasses and how it affects their mechanical properties. For this purpose, state-of-the-art preparation and in situ nanomechanical testing techniques, and computer simulations are applied.

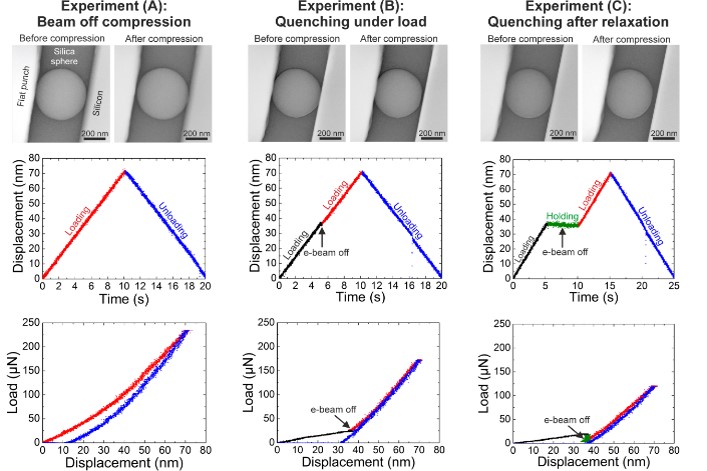

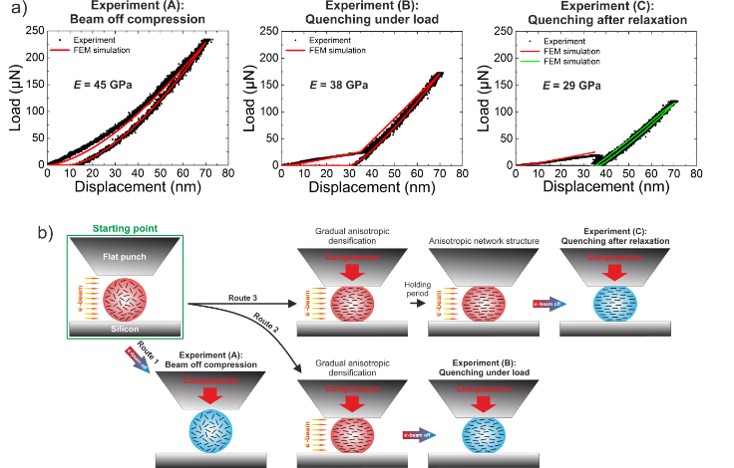

It was reported that in situ compression of nanoscale silica spheres under electron beam (e-beam) irradiation inside the transmission electron microscope (TEM) [6] and scanning electron microscope (SEM) [7], and in situ tensile elongation of amorphous silica fibers in the TEM [6], results in enormous ductility and superplasticity, respectively. We used this phenomenon to generate structural anisotropy in nanoscale silica spheres by beam-on / beam-off experiments (“e-beam quenching”) inside the TEM (see Fig. 1) and to explore its impact on their mechanical properties (see Fig. 2) [8,9]. E-beam quenching under load leads to a reduction of the effective Young’s modulus in compression direction (Fig. 2a), which we attribute to the “quenching-in” of a partially anisotropic silica network structure (Fig. 2b) [8,9]. Just recently, we developed a novel method for site-specific preparation and quantitative in situ tensile testing of nanoscale silica glass membranes inside the TEM [10]. This will help us to investigate the impact of structural anisotropy on the mechanical properties of glasses in tensile geometry.

Fig. 1: In situ compression experiments of nanoscale silica spheres carried out at different loading scenarios in the TEM. Reprinted from [9], Copyright Scripta Materialia, Inc.

Fig. 2: In situ TEM nanomechanical data complemented with finite element method (FEM) simulations; b) Proposed model for development of structural anisotropy in nanoscale silica spheres. Reprinted from [9], Copyright Scripta Materialia, Inc.

References

[1] R. Brückner, Glas. Berichte Glas. Sci. Technol. 69 (1996) 396.

[2] M.D. Lund and Y. Yue, J. Amer. Ceram. Soc. 93 (2010) 3236.

[3] S. Inaba et al., Nat. Mater. 14 (2015) 312.

[4] J. Wu et al., J. Chem. Phys. 131 (2009) 104504.

[5] A. Concustell et al., Scr. Mater. 64 (2011) 1091.

[6] K. Zheng et al., Nat. Commun. 1 (2010) 24.

[7] S. Romeis et al., Rev. Sci. Instr. 83 (2012) 95105.

[8] M. Mačković et al., Acta Mater. 79 (2014) 363.

[9] M. Mačković et al., Scr. Mater. 121 (2016) 70.

[10] M. Mačković et al., Front. Mater. 4 (2017) 10.