Stefan Romeis

Dr.-Ing. Stefan Romeis

Project description

Comminution in stirred media mills is a frequently applied top-down unit operation in process engineering. Starting from the size range of meters large scale production of particles on the nanometer scale has been demonstrated [1]. However, the general understanding of the involved complex processes is rather limited: Scale-up of comminution processes is mainly relying on the power draw and simple process models with only little physical meaning. Major factors which hamper a deepened process understanding are: i) The lack of experimental work dealing directly with the response of stressed submicron particles; ii) the distribution of the stresses applied in the comminution apparatus and iii) the absence of a direct measure for the aforesaid stress distributions.

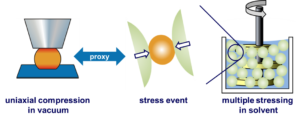

In this context, structurally and morphologically well-defined particulate material systems which were thoroughly characterized by complementary in situ compression experiments [2-4] are used as probe particles to shed light on wet comminution. So far, the influence of the used solvent on the physicochemical properties of comminution products obtained for glasses have been elucidated [4,5]. Furthermore, acting stress distributions in a laboratory scale stirred media mill were directly measured for the first time by metal particles: FEM modelling is used to link the observed deformations of the particles to the deformation energy transferred from the milling beads [6].

Fig.1: Well-characterized single particles are used as proxies to elucidate particle stressing in stirred media mills.

References

[1] C. Knieke et al., Powder Technology 195 (2009) 25.

[2] S. Romeis et al., Review of Scientific Instruments 83 (2012) 95105.

[3] J. Paul et al., Powder Technology 270 (2015) 337.

[4] S. Romeis et al., Journal of the American Ceramic Society 97 (2014) 150.

[5] S. Romeis et al. International Journal of Mineral Processing 156 (2016) 24.

[6] A. Strobel et al., Powder Technology 305 (2017) 652.