Thomas Przybilla

Dr.-Ing. Thomas Przybilla, Dr.-Ing.

Project description

In situ micromechanical testing of nanoporous gold (npg) offers insights into deformation mechanisms of nanoscale metal networks. Au ligaments act together as a three-dimensional open porous network of interconnected nanostruts resulting in high mechanical strength under compression and nanoindentation [1, 2]. With decreasing ligament size stresses close to the theoretical shear strength of Au have been reported in compression and nanoindentation experiments [2-4]. As the material is easy to process and the ligament size can be tailored within the nm-µm range without changing the relative density of the foam itself, npg can be regarded as a model material for studying size effects on nanoscale porous structures [5].

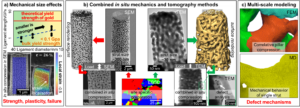

Objective of this study is to understand the deformation behaviour of nanoporous metal networks, in particular the interplay between the size of single struts, the nanoporous network morphology and the defect structure. To achieve that in situ small scale testing of npg in scanning electron microscopy (SEM) and transmission electron microscopy (TEM) is applied. By combining nano- and micromechanical testing of pillar structures with advanced tomographic imaging, a 3D characterization of the plastic deformation process in different states of deformation is achieved. For small strut sizes 360° electron tomography (ET) is applied enabling high quality reconstructions of the 3D morphology of npg without missing-wedge artefacts (cf. Figure 1b, right). Combining the geometric information with mechanical data from in situ testing in SEM and TEM the yield strength is precisely determined. Furthermore, the experimentally derived 3D data are used as input for large-scale molecular dynamics (MD) simulations in order to understand the role of strain localization and identify predominant defect processes (cf. Figure 1c).

For larger strut sizes mechanical testing and 3D structure analysis of npg pillars are carried out by in situ SEM and high-resolution X-ray tomography (Nano-CT), respectively (cf. Figure 1b, left). Image correlation analysis applied to in situ SEM image series reveals the evolution of local strain gradients during deformation (cf. Figure 1a, bottom) and, in particular, local yielding in the very early stages of deformation. The yield strength strongly depends on strut size revealing a clear size effect (cf. Figure 1a, top). The scale-bridging approach is complemented by in situ nanomechanical testing of single struts in TEM.

Figure 1: a) Investigation of strength, plasticity and failure by SEM in situ compression testing. b) Advanced 3D characterization of the deformation process on orientation-specifically prepared pillars by combining in situ micromechanics and tomographic techniques, namely X-ray tomography (b, left) and 360° ET (b, right) at different length scales. c) Correlative modeling by finite element method (FEM) and atomistic simulations based on real microstructural data.

References

[1] C. A. Volkert et al., Appl. Phys. Lett. 89 (2006).

[2] A. M. Hodge et al., Acta Mater. 55 (2007).

[3] J. Biener et al., Nano Lett. 6 (2006).

[4] M. Hakamada and M. Mabuchi, Scr. Mater. 56 (2007).

[5] E. Seker et al., Materials 2 (2009).